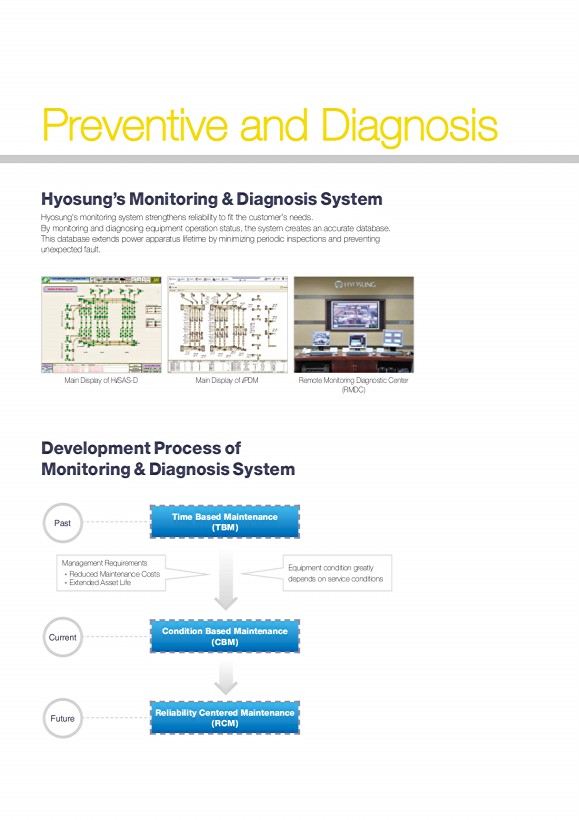

Preventive aand DDiagnosis Hyosung’s Monitoring & Diagnosis System Hyosungs monitoring system strengthens reliability to fit the customer’s needs. By monitoring and diagnosing equipment operation status, the system creates an accurate database. This database extends power apparatus lifetime by minimizing periodic inspections and preventing unexpected fault. Main Display of HiSAS-D Main Display of iPDM Remote Monitoring Diagnostic Center (RMDC) Development Process of Monitoring & Diagnosis System Time Based Maintenance Past (TBM) Management Requirements Equipment condition greatly •Reduced Maintenance Costs •Extended Asset Life depends on service conditions Condition Based Maintenance Current (CBM) Reliability Centered Maintenance Future (RCM)

I 14 15 Gas Insulated Switchgear GIS Supervision Partial Discharge(iPDM system : intelligent Partial Discharge Monitoring System) - By analyzing the installed equipment in the field, Hyosung provides clients with operation information by detecting the UHF signal that is generated when partial discharge occurs inside GIS. After analyzing the amount of discharge, causes and position of partial discharge is provided along with trends and risks. - It is possible to forecast inspection and lifetime of the equipment. When it reaches the allowable setting value, a warning message appears and provides instructions about maintenance. UHF Sensor Local Unit Main Unit Control Center LA Degradation Supervision - Hyosung’s customers may view the trends at the same time by monitoring total leakage and the 3 harmonic leakage currents of LA. - Warning messages occur when it reaches the allowable setting value and provides information about inspection and reminding life time. SF6 Gas Density - SF6 gas density is monitored by densimeter to check the condition of injected SF6 gas for isolation media of GIS. A sensor for each gas section is attached to monitor air tightness leakage. - If ground fault occurs inside of the GIS, it is possible to resolve the problem promptly by detecting the rising pressure. CB Operating Characteristics Monitoring - Diagnostic contents of CB operating consist of applied current of trip/closing coil, AUX contact and stroke curve, and each sensor is installed in GIS controller and Local Control Panel(LCP). - Signals measured from each sensor are analyzed by Hyosung algorithm and users can monitor normal or abnormal status of GIS operating by analytical results from Human Machine Interface(HMI). LA Measuring Equipment SF6 Gas Density Transducer CB Operating Current Transformer