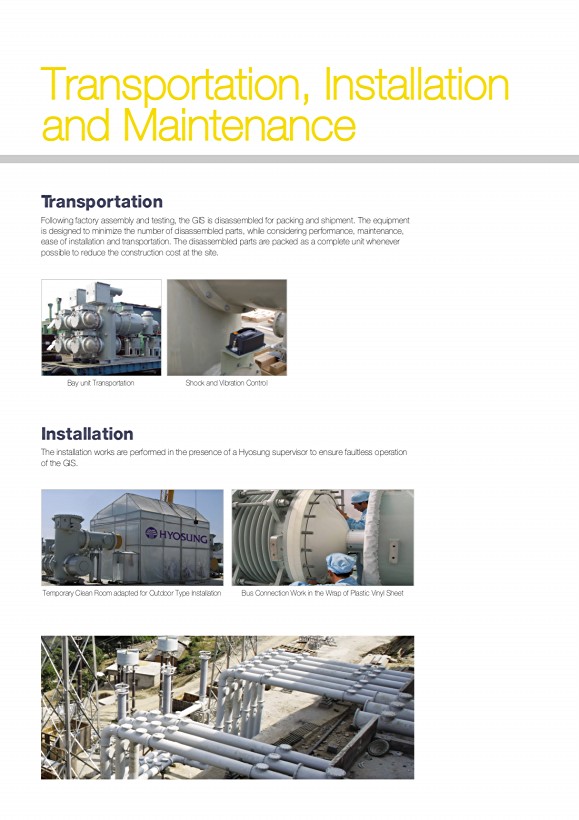

Transportation, IInstallation and MMaintenance Transportation Following factory assembly and testing, the GIS is disassembled for packing and shipment. The equipment is designed to minimize the number of disassembled parts, while considering performance, maintenance, ease of installation and transportation. The disassembled parts are packed as a complete unit whenever possible to reduce the construction cost at the site. Bay unit Transportation Shock and Vibration Control Installation The installation works are performed in the presence of a Hyosung supervisor to ensure faultless operation of the GIS. Temporary Clean Room adapted for Outdoor Type Installation Bus Connection Work in the Wrap of Plastic Vinyl Sheet

I 16 17 Gas Insulated Switchgear Maintenance The interior of GIS equipment is designed to eliminate almost all inspection and maintenance. To maintain the highest criteria of operating reliability, a routine inspection and maintenance schedule may be recommended. Routine Inspection and Maintenance Schedule Number oof Service switching CCB schedule Inspection operations* 1. Gas pressure and operating pressure check Ordinary Every 2 months 2. Recording number of Inspection operations of CB and lightning arrester Regular 1. Gas leakage test Every 500 times Every 3 years 2. Operating device inspection Inspection and lubrication Detailed Every 2,000 times Every 6 years 1. Detailed inspection of operating Inspection device * Number of switching operations at rated current of circuit breaker Dielectric Test UHF External Sensor UHF Internal Sensor