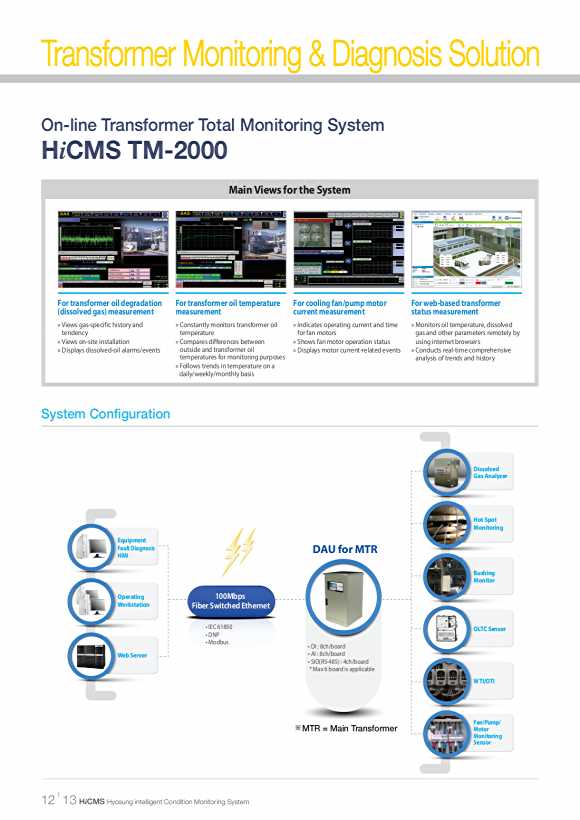

Transformer Monitoring & Diagnosis Solution On-line Transformer Total Monitoring System HiCMS TM-2000 Main Views for the System For transformer oil degradation For transformer oil temperature For cooling fan/pump motor For web-based transformer (dissolved gas) measurement measurement current measurement status measurement » Views gas‐specific history and » Constantly monitors transformer oil » Indicates operating current and time » Monitors oil temperature, dissolved tendency temperature for fan motors gas and other parameters remotely by » Views on‐site installation » Compares differences between » Shows fan motor operation status using internet browsers » Displays dissolved‐oil alarms/events outside and transformer oil » Displays motor current‐related events » Conducts real‐time comprehensive temperatures for monitoring purposes analysis of trends and history » Follows trends in temperature on a daily/weekly/monthly basis System Configuration Dissolved Gas Analyzer Hot Spot Monitoring Equipment Fault Diagnosis DAU for MTR HMI Bushing Monitor Operating 100Mbps Workstation Fiber Switched Ethernet • IEC 61850 OLTC Sensor • DNP • Modbus • DI : 8ch/board Web Server • AI : 8ch/board • SIO(RS-485) : 4ch/board * Max 6 board is applicable WTI/OTI Fan/Pump/ ※MTR = Main Transformer Motor Monitoring Sensor I 12 13 HiCMS Hyosung intelligent Condition Monitoring System

Monitoring and Diagnosis Items Transformer Oil Degradation (Dissolved Gas) •Performreal-timemeasurementoftheamountofH , CO, C H and 2 2 2 C H etc., generated in the transformer tank 2 4 •Issuesanalarmwhentheamountofdissolvedgasexceedsthesetlimits or shows an abrupt change •Performself-diagnosisandissuesalarmsintheeventofsensorfailure Hot Spot Monitoring •Robustfiberoptictemperaturesensorswhichwereinstalledon insulation spacer or surface of coil provide the exact temperature of hot spot directly •Usingtherealtimetemperature,efficienttransformeroperationis possible On-line Bushing Monitor •Bushingmonitoringsystemproviderealtimeinformationofbushing condition •Installcouplingunitsonbushingofpowertransformerinorderto measure PD activity and capacitance OLTC Monitoring •Indicatesthepresentvalueandtrendforcontactwear,torque,OLTCtemperature,andoperatingfrequency •Issuesalarmsandpresentsinspectionmessageswhenthe threshold value are exceeded Transformer Oil / Winding Temperature Indicates for each tank the present value and trend for top oil temperature, ambient temperature, load current, average oil temperature increase, and winding Hot-spot temperature Cooling Fan / Pump Motor Operating Condition Diagnoses the operating condition of transformer fans and pumps and the operating status of current fans and pumps, issues alarms when current exceeds the threshold value, and operates the TM-2000 system to inform the operator about what has caused the problem (e.g., power failure, motor failure, overload)