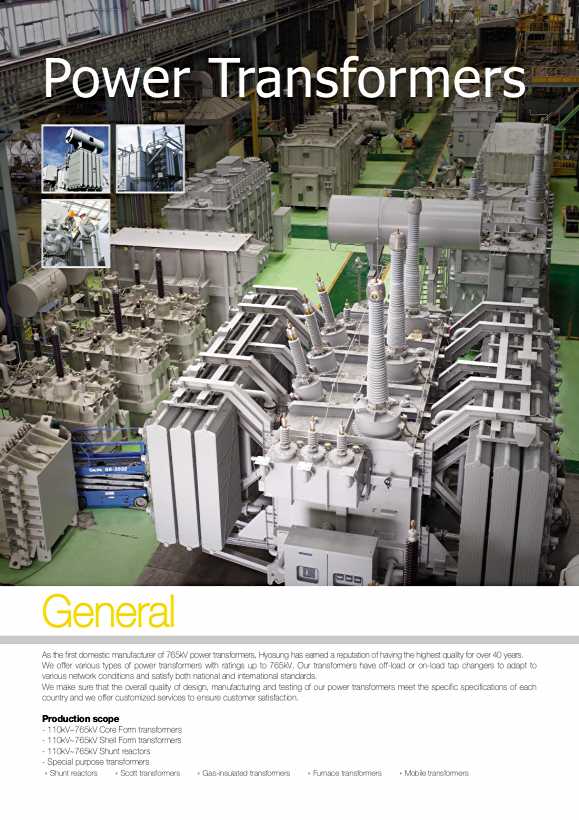

Power Transformers General As the first domestic manufacturer of 765kV power transformers, Hyosung has earned a reputation of having the highest quality for over 40 years. We offer various types of power transformers with ratings up to 765kV. Our transformers have off-load or on-load tap changers to adapt to various network conditions and satisfy both national and international standards. We make sure that the overall quality of design, manufacturing and testing of our power transformers meet the specific specifications of each country and we offer customized services to ensure customer satisfaction. Production scope - 110kV~765kV Core Form transformers - 110kV~765kV Shell Form transformers - 110kV~765kV Shunt reactors - Special purpose transformers •Shunt reactors •Scott transformers •Gas-insulated transformers •Furnace transformers •Mobile transformers

I 04 05 Power Transformers Technology Hyosung is the leading supplier of the power transformer industry. Starting with the development of the 154kV high-voltage transformer in 1969, Hyosung introduced the 345kV and the 765kV transformers subsequently for the first time in the country, and the sixth in the world. Hyosung’s power transformers are designed to withstand all environmental hazards. In the rated power range up to 2000MVA and operating voltage up to 765kV, these transformers have off- load or on-load tap changers to adapt them to various network conditions. Hyosung manufactures transformers under IEC, JEC, ANSI, BS and all required national standards. Hyosung offers individual solutions for satisfying requirements related to types of operation, low noise and low losses, connection technology, type of cooling, transportation, installation and so on. Various Types Various types of transformers are available according to the specific requirements including single phase and three phase transformers, auto and multi-winding transformers, reactors and transformers for special applications such as furnace transformer, rectifier transformer and more. Fit Design If there are any constraints related to transportation or site conditions, we can offer fit design transformer to ensure smooth shipping and installation. We also possess experience in transportation by airplanes. Safety To ensure safe operation of our transformers, potential hazards are identified and eliminated at all stages. Safety during installation is ensured by extending on-site support to customers by our experienced and efficient supervisor. Flexible Manufacturing System Our production flow management system is fully computerized and automatically controlled to prioritize and finalize the manufacturing schedules based on delivery dates. This system yields the most optimized use of resources and also enables us to accommodate the unexpected and/or urgent orders by customers with shorter time delivery requirements. Simple Handling and Maintenance Compact design of our transformers ensure easy and smooth handling of transformers whereas Efficient design and manufacturing process and use of reliable components and accessories from reputed manufacturers ensure the trouble free operation rendering low maintenance cost of the equipment. Customized Solutions Tailor-made customized transformers can also be supplied based on the specific requirements. Smart Grid Enabled Design, manufacture, installation, and maintenance &repair of electric power facilities (transformer, GIS, and switchboard) are based on technology and knowhow accumulated over the past 35 years. By linking Hyosung’s new preventive diagnostic system, users can diagnose the status of the equipment and schedule inspections through data received in real-time, including partial discharge and insulation oil deterioration, OLTC monitoring, insulation oil temperature, operation status of cooling fans, pumps, motor operation, and oil filter pressure. World Class Technology and Capacity to Meet Global Challenges •Type / Rating - Core Form : Up to 3ph 765kV 2000MVA - Shell Form : Up to 3ph 765kV 1500MVA Core Form Shell Form Transformer Production Hall