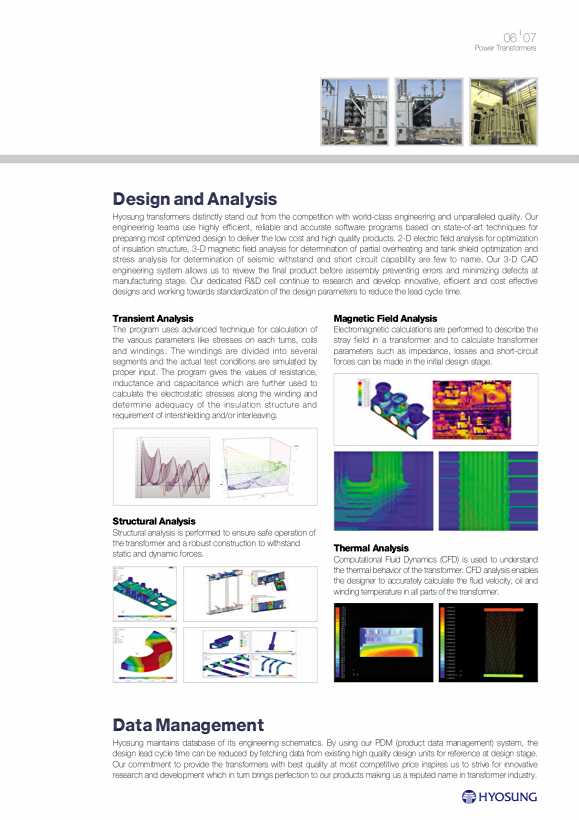

I 06 07 Power Transformers Design and Analysis Hyosung transformers distinctly stand out from the competition with world-class engineering and unparalleled quality. Our engineering teams use highly efficient, reliable and accurate software programs based on state-of-art techniques for preparing most optimized design to deliver the low cost and high quality products. 2-D electric field analysis for optimization of insulation structure, 3-D magnetic field analysis for determination of partial overheating and tank shield optimization and stress analysis for determination of seismic withstand and short circuit capability are few to name. Our 3-D CAD engineering system allows us to review the final product before assembly preventing errors and minimizing defects at manufacturing stage. Our dedicated R&D cell continue to research and develop innovative, efficient and cost effective designs and working towards standardization of the design parameters to reduce the lead cycle time. Transient Analysis Magnetic Field Analysis The program uses advanced technique for calculation of Electromagnetic calculations are performed to describe the the various parameters like stresses on each turns, coils stray field in a transformer and to calculate transformer and windings. The windings are divided into several parameters such as impedance, losses and short-circuit segments and the actual test conditions are simulated by forces can be made in the initial design stage. proper input. The program gives the values of resistance, inductance and capacitance which are further used to calculate the electrostatic stresses along the winding and determine adequacy of the insulation structure and requirement of intershielding and/or interleaving. Structural Analysis Structural analysis is performed to ensure safe operation of the transformer and a robust construction to withstand Thermal Analysis static and dynamic forces. Computational Fluid Dynamics (CFD) is used to understand the thermal behavior of the transformer. CFD analysis enables the designer to accurately calculate the fluid velocity, oil and winding temperature in all parts of the transformer. Data Management Hyosung maintains database of its engineering schematics. By using our PDM (product data management) system, the design lead cycle time can be reduced by fetching data from existing high quality design units for reference at design stage. Our commitment to provide the transformers with best quality at most competitive price inspires us to strive for innovative research and development which in turn brings perfection to our products making us a reputed name in transformer industry.

Products aand DDetails Core Form Transformers Core form transformer refers to the structure of locating low-pressure/high-pressure winding surrounding core to concentric circle. Characteristic - Compact structure - Easy assembly - Linear potential distribution - Circular form with short circuit strength - Easy inspection and repair Item Phase Rated Voltage Capacity 765kV Transformer 1 ph 765/345/23kV 667MVA 345kV Transformer 3 ph 345/230/13.8kV 700MVA 230kV Transformer 3 ph 245/23kV 875MVA 765kV Transformer 345kV Transformer 230kV Transformer