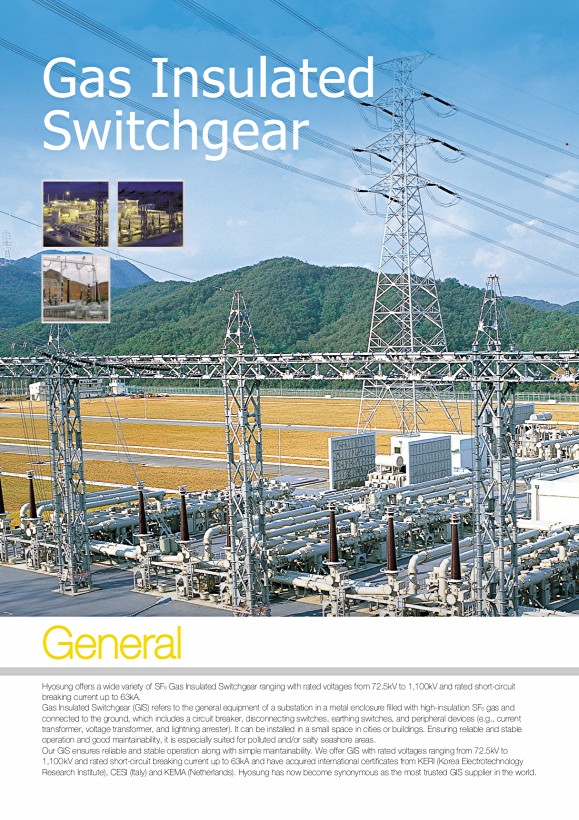

Gas Insulated Switchgear General Hyosung offers a wide variety of SF6 Gas Insulated Switchgear ranging with rated voltages from 72.5kV to 1,100kV and rated short-circuit breaking current up to 63kA. Gas Insulated Switchgear (GIS) refers to the general equipment of a substation in a metal enclosure filled with high-insulation SF6 gas and connected to the ground, which includes a circuit breaker, disconnecting switches, earthing switches, and peripheral devices (e.g., current transformer, voltage transformer, and lightning arrester). It can be installed in a small space in cities or buildings. Ensuring reliable and stable operation and good maintainability, it is especially suited for polluted and/or salty seashore areas. Our GIS ensures reliable and stable operation along with simple maintainability. We offer GIS with rated voltages ranging from 72.5kV to 1,100kV and rated short-circuit breaking current up to 63kA and have acquired international certificates from KERI (Korea Electrotechnology Research Institute), CESI (Italy) and KEMA (Netherlands). Hyosung has now become synonymous as the most trusted GIS supplier in the world.

I 04 05 Gas Insulated Switchgear Technology Compact Design The installation space that is required is about 1/10~1/20th than that of conventional air-insulated substations which makes it possible to install GIS within a building. Safety Enhanced insulating properties and reduced long-term operational costs by means of a sealed metal enclosure filled with SF6 gas which assures first-rate reliability, thus making it suitable for highly populated and urban areas. Superior Reliability Personnel safety is ensured by an earthed enclosure, numerous interlocks, and lockout devices. Greater stability is provided during earthquakes and the perfect enclosure protects from loss or damage from salt, dirt, weather, and lightning. While the SF6 gas insulation prevents deterioration, the partition of the gas prevents accidents from occurring. Elimination of Periodic Maintenance Virtually eliminates long-term maintenance costs and contamination of critical components by means of SF6 gas-filled metal enclosures, automatic monitoring of operating mechanisms, and the SF6 gas system. Installation & Transportation Installation time and costs are reduced since the system is shipped in a completely assembled bay or by unit.